Expert Lecture - Mechanical Engineering

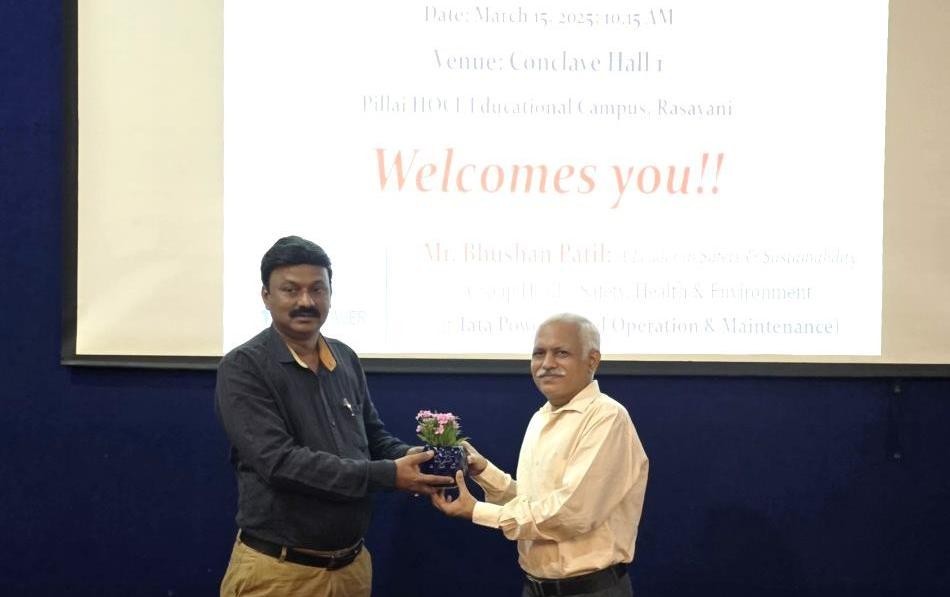

| Title of the Expert Talk | Innovations and Best Practices in Industrial Safety |

| Name of the Speaker | Mr. Bhushan D Patil |

| Designation of the Speaker | Group Head HSE |

| Organization of the Speaker | TATA Power Wind Business |

| Date of the Expert Talk | March 15, 2025, 10:15 AM |

| Faculty In-charge | Prof. Arjun Deshmukh, PHCET - Diploma |

| Venue of the Expert Talk | Conclave Hall 1, Pillai HOCe Educational Campus, Rasayani |

| Targeted Beneficiaries | Second, and First-year Diploma in Mechanical Engineering |

| Targeted Course | Production Processes and Manufacturing Technology |

Mr. Bhushan D Patil is a seasoned professional with over 13 years of experience in Health, Safety, and Environment (HSE) management. Currently serving as the Group Head for Safety, Health & Environment at Tata Power’s Wind Operation & Maintenance division, Mr. Patil is responsible for overseeing safety operations across the wind energy sector in India. His work ensures the creation of a safer and more sustainable work environment within the industry.

His educational qualifications include a Bachelor of Science (B.Sc.), a Master of Business Administration (MBA), a Diploma in Electrical Engineering, and an Advanced Diploma in Industrial Safety. He holds various certifications, including NEBOSH (National Examination Board in Occupational Safety and Health) certification from the K.. Mr. Patil is also a Lead Auditor for ISO 45001:2018 (Occupational Health and Safety), ISO 22301:2019 (Business Continuity Management System), and a core member of ISO 9001:2015 (Quality Management System) implementation. With a focus on enhancing safety, compliance, and risk management, he has contributed significantly to the energy sector by promoting a secure and sustainable work environment. Mr. Patil has been a key driver of safety culture and regulatory compliance across wind energy operations.

Key Points of the Expert Talk

The lecture began with an introduction to industrial safety, highlighting its crucial role in preventing accidents and ensuring the health and well-being of workers. Mr. Patil emphasized the importance of safety not just for legal compliance but also as a means of safeguarding the workforce and improving productivity.

He then moved on to discuss the different types of industrial hazards, including physical, chemical, biological, ergonomic, and psychosocial hazards. These hazards are prevalent across various industries, and understanding them is the first step towards implementing effective safety measures. The expert highlighted key safety practices such as the use of Personal Protective Equipment (PPE), proper training, machine safety, and fire safety procedures. He explained how each of these practices contributes to reducing the risk of accidents in the workplace. PPE was stressed as an essential element for worker protection, and Mr. Patil illustrated how regular safety training and awareness programs are vital in ensuring employees are prepared to handle emergencies.

Mr. Patil also discussed several important safety regulations and acts, such as the Factories Act, 1948, The Mines Act, 1952, The Workmen’s Compensation Act, 1923, The Employees’ State Insurance Act, 1948, and The Environment Protection Act, 1986. These acts set the legal framework for ensuring industrial safety and protecting workers’ rights. He provided an overview of how these laws play a crucial role in maintaining a safe working environment and ensuring workers’ welfare.

The lecture also covered accident prevention strategies, emphasizing the need to identify potential hazards before they result in accidents. Mr. Patil explained how regular safety audits and proactive hazard identification can significantly reduce the risk of incidents. Furthermore, he spoke about emergency response and first aid, underscoring the importance of timely intervention in case of accidents to minimize harm.

Mr. Patil also emphasized the critical role that workers play in maintaining safety standards. He encouraged students to take responsibility for their own safety, report unsafe practices, and engage in creating a culture of safety within their future workplaces. This was linked to the broader idea of building a strong safety culture within organizations, where every employee is committed to safety. Finally, Mr. Patil shared insights into technological advancements in safety, including the use of automation, safety sensors, and real-time monitoring systems. These technologies help in identifying risks before they escalate, ensuring a safer working environment through continuous monitoring.

Innovative Ideas, Strategies, or Technologies Mentioned/ Real-World Examples/ Case Studies Discussed

Throughout the session, Mr. Patil shared real-time case studies and examples from Tata Power’s Wind Operations, demonstrating how innovative safety measures have been successfully implemented. He provided insights into the best practices followed in the energy sector and discussed how emerging technologies such as AI-powered safety systems, wearable health monitoring devices, and advanced safety sensors are revolutionizing industrial safety. These technologies help in preventing accidents by providing real-time data, detecting hazardous conditions, and enabling swift responses to potential risks. Mr. Patil also stressed the importance of continuous safety improvements and keeping up with the latest advancements to maintain a high standard of safety in the workplace.

Conclusion

The expert lecture provided valuable insights into the importance of industrial safety and the best practices that should be followed to ensure a safe and productive work environment. Mr. Bhushan D Patil’s wealth of experience and practical knowledge made the session highly informative for the students.

His discussion on innovations in safety, real-time case studies, and the role of technology in modernizing safety practices gave students a comprehensive understanding of the evolving safety landscape in industries. The session was a great learning experience for the students, reinforcing the need for a proactive approach to industrial safety and inspiring them to prioritize safety in their future careers.

| Title of the Expert Talk | Best Practices in Inspection and NDT for Heavy Engineering Industry |

| Date of the Expert Talk | March 15, 2025, 01:45 PM |

| Name of the Speaker | Mr. Rahul Joshi |

| Designation of the Speaker | Sr. Engineer, Inspection and Quality Control |

| Organization of the Speaker | TUV India Private Limited, Pune |

| Faculty In-charge | Prof. Arjun Deshmukh, PHCET - Diploma |

| Venue of the Expert Talk | Conclave Hall 1, Pillai HOCL Educational Campus, Rasayani |

| Targeted Beneficiaries | Second, and First-year Diploma in Mechanical Engineering |

| Targeted Course | Metrology and Measurement and Mechanical Engineering Materials |

Brief Profile of the Speaker

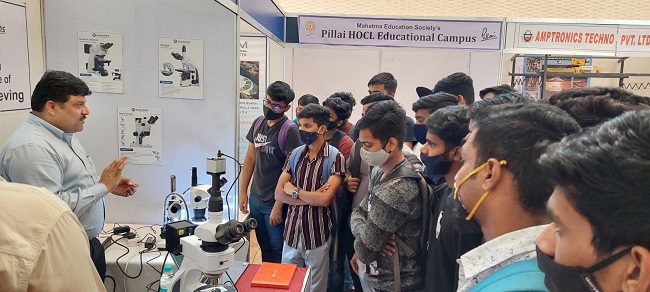

Mr. Rahul Joshi is an experienced Inspection and Quality Control (QC) Engineer with a specialization in heavy engineering, fabrication, and Non-Destructive Testing (NDT). He currently works as a Senior Inspection Engineer at TUV India Private Limited with over 4 years of experience.

His career journey has taken him through esteemed companies such as John Galt International, Vipras Corporation, Godrej & Boyce, and Paramount. Mr. Joshi is a specialist in pressure vessels and holds expertise in NDT Level 2 inspections. We are proud to recognize him as a distinguished alumnus of the 2020 batch of Pillai HOC Polytechnic, Rasayani, now recognized as Pillai HOC College of Engineering and Technology now.

Key Points of the Expert Talk

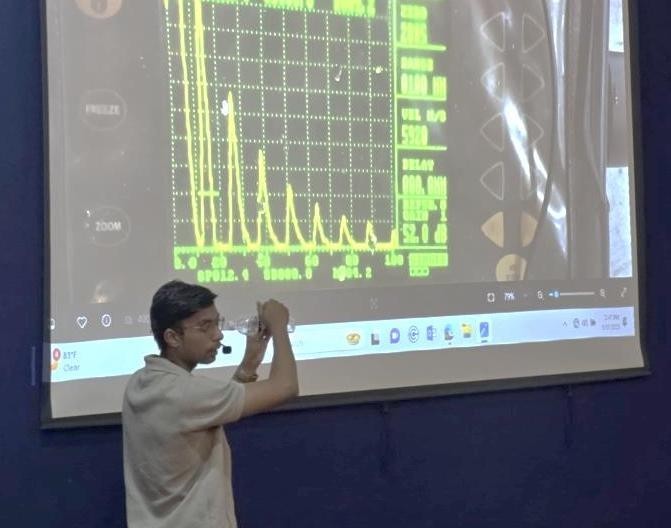

The Expert Talk covered various essential Non-Destructive Testing (NDT) techniques employed in the heavy engineering industry. Mr. Joshi discussed key methods, including Ultrasonic Testing (UT), a technique that uses high frequency sound waves to detect flaws in materials; Radiographic Testing (RT), which utilizes X-rays or gamma rays to inspect the internal structure of materials; and Magnetic Particle Testing (MT), used for detecting surface and near-surface discontinuities in ferromagnetic materials. The talk also covered Liquid Penetrant Testing (PT), a surface inspection method to reveal cracks and leaks, and Eddy Current Testing (ET), which detects surface and sub-surface defects by generating an electromagnetic field.

Additional methods discussed included Acoustic Emission Testing (AE), where sounds emitted by materials under stress are monitored, and Thermography, which uses infrared cameras to detect temperature variations indicating issues like insulation problems or mechanical failure. The session also addressed Leak Testing (LT), an essential method for detecting leaks in sealed systems, commonly used in pressure vessels and pipes.

Innovative Ideas, Strategies, or Technologies / Real-World Examples/ Case Studies Discussed

Mr. Joshi shared real-time case studies and best practices for each of the NDT techniques. These case studies provided valuable insights into their application in real-world scenarios, helping students understand how these inspection methods are utilized effectively in the heavy engineering sector. Innovative strategies included the integration of advanced technology in ultrasonic testing and thermography, which improves detection capabilities and reduces inspection times.

Mr. Joshi also discussed the use of robotic systems in some industries for automated NDT, which enhances accuracy and reduces human error. Furthermore, he provided examples of field-based applications where a combination of NDT methods is employed for more comprehensive inspections, ensuring the reliability and safety of critical infrastructure.

Conclusion

The Expert Talk was an enriching experience for the students, offering them in-depth knowledge about various NDT techniques used in the heavy engineering industry. Mr. Rahul Joshi’s practical insights and real-world case studies highlighted the importance of inspection and quality control in ensuring the safety and performance of engineering structures. The session fostered a better understanding of how students can apply these techniques in their future careers, particularly within the domain of mechanical engineering. The session concluded with a Q&A segment where students interacted with Mr. Joshi, clarifying doubts and discussing career opportunities in the field of NDT and inspection.

| Title of the Expert Talk | Expert Insights from Automation Leader - Oetiker India |

| Date of the Expert Talk | March 06, 2025, 11:30 AM |

| Name of the Speaker | Binod Prasad |

| Designation of the Speaker | Head HR, Oetiker India Private Limited |

| Organization of the Speaker | Oetiker India Private Limited Patalganga MIDC |

| Faculty In-charge | Ms Divya Nair PHCET - T&P Cell |

| Venue of the Expert Talk | Seminar Hall, Third Floor Engineering Bulding |

| Targeted Beneficiaries | Second year Diploma in Mechanical Engineering |

| Targeted Course | Production Processes and Manufacturing Technology |

| Number of Beneficiaries | 58 students |

Binod Prasad is an experienced HR leader currently serving as the Head of HR for Oetiker India Private Limited and overseeing HR operations across India and ASEAN for Oetiker Group since April 2022. With over 20 years of experience, he has held various key positions, including Senior Manager

– HR Operations at ZF Group, where he managed HR operations, payroll, and project management, and Manager – HR at ZF Group, focusing on enhancing employee engagement and internal policies.

His earlier roles include Executive HR & Admin at Endurance Magneti Marelli Shock Absorbers, Officer HR & Admin at Jayashree Polymers Pvt Ltd, and Trainee HR at Bajaj Auto Finance. Binod’s expertise spans HR operations, policy formulation, human resource development, and talent management, making him a seasoned professional in the field.

During the talk, Mr. Binod Prasad shared valuable insights into the various technologies driving Oetiker India’s manufacturing processes. He began by discussing the pivotal role of automation in enhancing production efficiency and product quality. He explained how Oetiker India has adopted cutting-edge automation technologies, such as robotic systems and automated assembly lines, which play a crucial role in reducing human error, improving precision, and ensuring consistency in the production of their high-quality clamps and rings. Mr. Prasad also emphasized the importance of integrating digital tools into manufacturing. He explained how Oetiker uses advanced digital simulation and modeling software to optimize product designs before entering production. This allows the company to test and refine designs in a virtual environment, ultimately reducing the time and costs associated with prototyping and ensuring that the final product meets the highest quality standards.

Another important point discussed was the scalability and flexibility of Oetiker’s manufacturing processes. Mr. Prasad highlighted the company’s use of modular automation systems that enable them to easily scale production based on market demand. This flexibility ensures that Oetiker can efficiently manage varying production volumes while maintaining product quality and minimizing waste. Furthermore, Mr. Prasad addressed the role of Industry 4.0 technologies, including the Internet of Things (IoT) and data analytics, in Oetiker’s manufacturing operations. These technologies enable real-time data collection and analysis, allowing the company to optimize production processes and predict potential issues before they occur, thereby minimizing downtime and improving overall operational efficiency.

Innovative Ideas, Strategies, or Technologies / Real-World Examples/ Case Studies Discussed

The talk provided insights into the innovative technologies employed by Oetiker India, particularly the integration of robotics and automated assembly lines. These advancements enable the company to produce high-precision products like the DualHook Adjustable Ear Clamps, ToothLock Ear Clamps, and StepLess Ear Clamps with enhanced speed, consistency, and durability, while maintaining stringent quality standards.

The talk further covered Oetiker’s use of modular automation systems, allowing flexible production volumes based on market demand, ensuring quality and efficiency despite fluctuating needs. Additionally, Mr. Prasad discussed the real-time monitoring, predictive maintenance, and optimized manufacturing processes, ultimately reducing downtime and improving system reliability.

Conclusion

The expert talk provided students with a comprehensive understanding of the cutting-edge technologies driving modern manufacturing. The real-world examples and case studies discussed during the session offered students a valuable perspective on how innovative technologies are shaping the future of manufacturing and automation. It was an excellent opportunity for students to learn about the technological advancements that are transforming the manufacturing industry and how companies are leveraging these innovations to stay competitive in the global market.

| Title of the Expert Talk | Modern Trends in Air Conditioning |

| Date of the Expert Talk | January 16, 2025 |

| Name of the Speaker | Mr Kalyaan Sundaresan |

| Designation of the Speaker | Consultant-BlueStar India Ltd |

| Faculty In-charge | Ms Divya Nair PHCET - T&P Cell |

| Venue of the Expert Talk | Conclave Hall 1, Pillai HOCL Educational Campus, Rasayani |

| Targeted Beneficiaries | Third-year Diploma in Mechanical Engineering |

| Targeted Course | Refrigeration & Air Conditioning and Thermal Engineering |

| Objective | To make aware all students about recent trends in air conditioning. |

The expert talk on “Modern Trends in Air Conditioning” was organized by the Training and Placement Cell of PHCET College to provide engineering students with new technologies in air conditioning industry. The expert talk aimed to bridge the gap between academic knowledge and practical application.

Course content / Description

- Smart systems and energy efficient refrigerants.

- Improved filters, geothermal systems and variable speed motors.

- Inverter and dual inverter compressors.

- Multi-split and zoned cooling systems

- Awareness among students regarding corporate world, difficulties and challenges in corporate culture.

Detailed Description

Mr Sunderasan Kalyaan is a mechanical engineer from Annamalai University and a PG in Public Administration from Madras University. He is also a certified energy auditor. He is presently working as a consultant to BlueStar India Ltd. Speaker explained recent advancement in air conditioning system to maximize efficiency and reduce energy consumption.

Speaker explained about smart systems which uses real time data to optimize heating, cooling and ventilation. Brief regarding energy efficient refrigerants which are designed to be more efficient and eco-friendly. Speaker also explained various trends such as geothermal systems, renewable energy sources, variable speed motors etc.

Conclusion

The expert talk on “Modern Trends in Air Conditioning” was a highly beneficial event for engineering students, offering valuable industry insights, recent trends in air conditioning system. The Training and Placement Cell of PHCET College extends its gratitude to Mr. Sundaresan Kalyaan for his valuable contributions and efforts in making this expert talk a success.

Name of Invitee: Mr. Vishvashree V. Karadkar

Name of Invitee: Mr. Pratik Mhatre (Maharashtra State Electricity Distribution Company Ltd.)

Name of Invitee: Mr. Keshav Chaughule

Name of Invitee: Mr. Prasad Awti (Philip Machine Tool Pvt. Ltd. )

Name of Invitee: Mr. Dinesh Shantaram Auti (Director: PERLC)

Name of Invitee: Mr. Vaibhav Vasant Kumar Survase (Director: Survase Education LLP)

Name of Invitee: Mr. Jayant Franklin & Mr. Sanket Saksena (H.R Team – Reliance Industries)

Name of Invitee: Mr. Ameet Pandey (Manager – Questech)

Name of Invitee: Mr. Ameet Pandey (Manager – Questech)

Name of Invitee: Mr. Manibhushan Tiwari (COSQUO Consulting India Pvt. Ltd.)

Date: 13th April, 2022

Solar Power – Mahindra Sustain by Kamlesh Upadhyay

Date: 7th April, 2022

Intellectual Property Rights & Patents by Dr. B. K, Sarkar

Date: 31st March, 2022

Importance of Packaging & Packaging Materials by Sudarshan Kullur (Director TVPS)

Date: 31st March, 2022

3D Printing for Different Applications by Jitendra Damle (Director Meshit 3D)

Date: 31st March, 2022

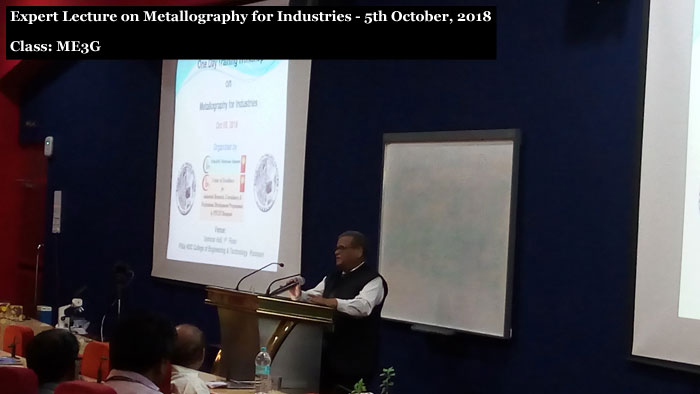

Metallographic Techniques by Shriranga Patwardhan (µ-tek Solutions)

Date: 30th March, 2022

Career Guidance & Personality Development by Ramesh Sathe

Date: 30th March, 2022

Electrical Safety by Mr Ramesh Sathe

Date: 30th March, 2022

Opportunities of engineers in CAD / CAE by G. V Patil Sir

Date: 23rd November, 2021

National Apprenticeship Training Scheme by N.C. Gangde

Date: 17th November, 2021

Sambhav Create Future Through Entreprenureship by Mr. Kantharao D. Jinna

Name of Invitee:

Mr. Pramod Daspute

Date: 17th November, 2021

Sambhav Create Future Through Entreprenureship

Mr. Kantharao D. Jinna

Name of Invitee:

Mr. Pramod Daspute

Name of Invitee:

Dr. R. C. Prasad

Name of Invitee:

Mr. Ganesh Chafekar

Name of Invitee:

Mr. Nizamuddin B.

Name of Invitee:

Dr. Kalyan Swami

Name of Invitee:

Mr. Sanjay Govilkar (Dnyan Prasan Seva, Pen)

Name of Invitee:

Mr. Sanjay Govilkar (Dnyan Prasan Seva, Pen)

Name of Invitee:

Komal Pawar (Engineering and Project Co-ordinator, Engineering consolidated, Mahim, Mumbai)

Name of Invitee:

Mr. Dinoj Kumar (4th Engineer (D. G. Shipping), Anglo Eastern Ship Management Ltd. Mumbai)

Name of Invitee:

Mr. Sunil V. Shete (Dairy Science & AH, Sugar Tech, MBA Marketing)

Name of Invitee:

Mr. Saksham Korde (Campus Recruitment Trainer, Mumbai)

Name of Invitee:

Mr. Maninder Singh (Embeded Engineer, Vision World Tech Pvt. Ltd., Navi Mumbai)

Name of Invitee:

Mr. Maninder Singh (Embeded Engineer, Vision World Tech Pvt. Ltd., Navi Mumbai)

Name of Invitee:

Mr. Prashant Chaudhari (Owner S. P. Engineering Pvt. Ltd., Pune)

Name of Invitee:

Mr. Shreyas Patil (Managing Director, Strings Electronics Pvt. Ltd., Pen, Raigad)

Name of Invitee:

Mr. Vikram Mane (Dy. Engineer, B.E.S.T., Mumbai)

Name of Invitee:

Mr. Popat Khandare (Dy. Director, {Technical}, Maharashtra Electricity Regulatory Commission, Mumbai)

Name of Invitee:

Mr. Atul Kambale (Manager, Service Marketing and Digital Projects, Volkswagen Group Sales India, Pvt. Ltd., Mumbai)

Name of Invitee:

Mr. Sanis Mhatre (Purchase Officer, Supply Chain Department, Johnson Matthey Chemical India Pvt. Ltd., Taloja MIDC, Raigad)

Name of Invitee:

Mr. Sandeep Veerkar (Training Manager, Pillai HOCL Campus, Rasayani)

Name of Invitee:

Mr. Wilson Pinto (Lecturer, Pillai Institute of Information Technology, Engineering, Media Studies and Research, Panvel)

Name of Invitee:

Ms. Shweta Bhagat (Lecturer, Changu Kana Thakur, New Panvel)

Name of Invitee:

Ms. Divya Tiwari (TPO, Pillai HOC Educational Campus, Rasayani)

Name of Invitee:

Mr. K. R. Onkar Sir (Executive Secretary, PRIA)

Name of Invitee:

Mr. Vikram Mane (Assistant Engineer, BEST Bus Depot, Goregaon)

Name of Invitee:

Mr. Suhas Deshmukh (Sr. Lecturer, B. L. Patil Polytechnic, Khopoli)

Name of Invitee:

Prof. R. B. Randale (Assistant Professor I.T. Department, Pillai HOC College of Engineering and Technology, Rasayani)